Hospitals in Gaza 3D print their own equipment

Published: 2017-09-06 17:38

Last Updated: 2024-04-18 23:30

Even the most basic of tools used by doctors is a luxury in Gaza: the stethoscope.

Images surfaced from al-Jazeera show Gaza's largest hospital - al-Shifa, having to 3D print their own stethoscope as a result of shortages from the Israeli blockade. Al-Shifa currently only has 2 stethoscopes, with doctors having to resort to pressing their ears against a patient's chest to hear their heartbeat.

Canadian doctor Tarek Loubani told al-Jazeera that he and three of his peers are working to remedy shortages of equipment. As part of the Glia team, their goal is to mass-produce high-quality and low-cost medical devices to meet shortages in the Gaza strip.

They have recently just received their first batch of stethoscopes. In approximately two hours, a printer will finish printing all the pieces to form the tested and approved 3D printed stethoscope - the first of its kind in the Gaza Strip.

"It looks like a toy, but the quality is just as good as the leading brands," Mohammed Abu Matar, 31, told Al Jazeera, adding that it only costs 3 dollars to produce, compared to industry-leading models which cost roughly 200 dollars.

Due to the decade-long Israeli-Egyptian blockade, there has been a devastating shortage of medical equipment which Israel deems can be put to "dual-use", namely military purposes.

How a stethoscope can be used for military use is unclear.

Affordability is also another major issue, considering that a doctor's salary in Gaza is equivalent to a high-quality stethoscope at 300 dollars.

"But those paths get disrupted really easily," said Loubani. "I can no longer travel through Egypt, because I was in jail there. On my way into Israel, they searched me. Even very simple medical equipment isn't allowed in ... With huge disruption in trade routes, it became obvious that we have to start making things in Gaza if we're ever to be able to have a reliable supply of medical equipment."

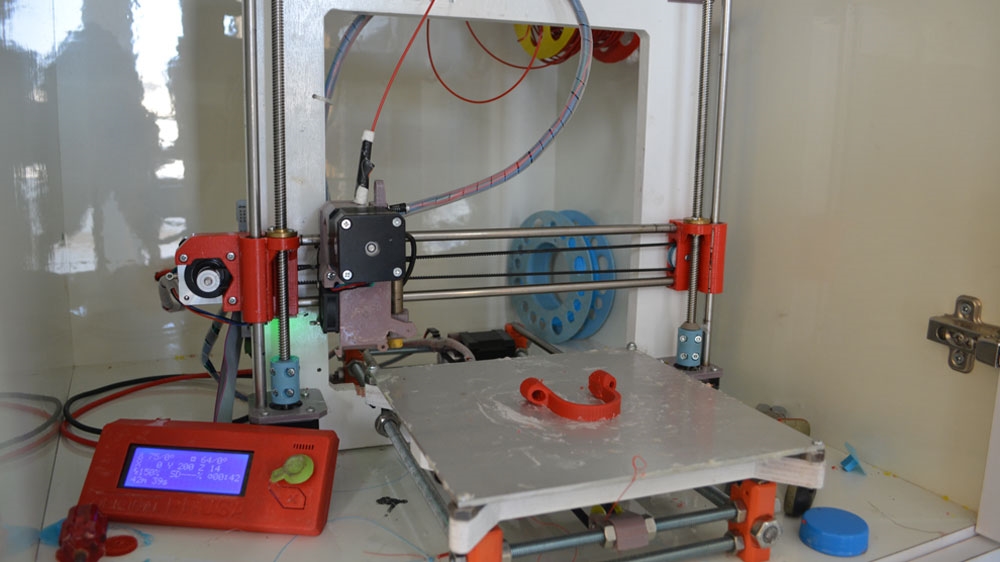

Abu Matar, a graduate student in telecommunications, faces the same problem in Gaza forcing him to built his own machinery, including negative ion and ozone generators. Since, he has successfully built a 3D printer, which is illegal to have in Gaza, to solve the problem of missing pieces.

Matar scraped together all necessary parts, and followed open source designs online to build the 3D printer himself. He now runs the first 3D printing business in Gaza, called Tashkeel 3D.

Matar used open source 3D printing designs, and modified them to meet the needs for hospital equipment.

Having completed the stethoscope, clinical testing is currently under way for their printed tourniquet and pulse oximeter, which shows how much oxygen is circulating in a body.

However, doctors and specialists urge to proceed with caution. "You have a very special problem in Gaza; a rocket could come through this window and this place is gone. If that happens, what's supposed to happen with this work?" asks Loubani.

This is why Hatar and other specialists plan on making information more available along the strip, so that it can be replicated in the event of further crisis.